Businesses that operate vehicles, machinery, or generators constantly face the challenge of balancing operational efficiency with costs. One of the most effective strategies to reduce long-term expenses is investing in high quality motor oils and lubricants. While premium oils may come with a slightly higher upfront cost, they provide tangible benefits: lower maintenance, extended engine and machinery life, smoother performance, and improved fuel efficiency.

Nicopoil produces oils engineered for modern engines and demanding operational environments. Understanding the full advantages of high quality Motor Oils and Lubricants enables businesses to make informed choices that protect assets and improve cost management.

Why Proper Lubrication Is Critical

Lubrication is essential to maintaining engine and machinery health. Every moving part in an engine generates friction, produces heat, and is exposed to contaminants. Left unchecked, these factors accelerate wear, reduce efficiency, and can lead to premature failure.

High-quality oils act as a protective barrier. They reduce friction, manage heat, resist contamination, and maintain their viscosity under extreme operating conditions. By doing so, premium oils prevent sludge buildup, corrosion, and unnecessary wear.

Low-quality oils, in contrast, break down faster. They struggle to protect components under high stress and extreme temperatures, leading to frequent maintenance, unexpected downtime, and higher operational costs.

Reduced Maintenance Costs

Using high quality motor Oils and Lubricants directly reduces the frequency and severity of engine and machinery repairs. Better lubrication prevents excessive friction and heat, slows component wear, and keeps engines cleaner.

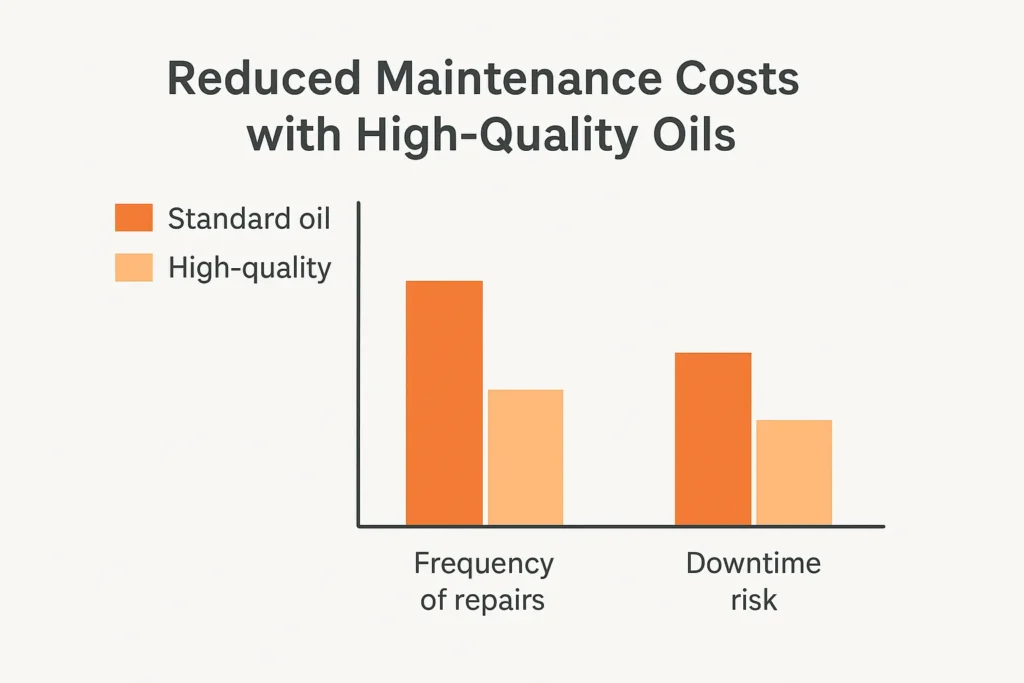

This chart clearly shows the difference between standard and high-quality oils. Businesses can see how fewer repairs and lower downtime translate into real cost savings over time. For operators managing multiple vehicles or machines, these savings compound significantly over the year.

Maintenance Comparison:

| Maintenance Aspect | Standard Oil | High-Quality Oil |

|---|---|---|

| Frequency of repairs | High | Low |

| Engine cleanliness | Average | Excellent |

| Component wear | Moderate | Minimal |

| Service interval | Short | Extended |

| Downtime risk | High | Low |

Practical Insight: Businesses that switch to premium oils often see maintenance intervals extended by several months, meaning fewer labor hours and reduced part replacement costs. For a fleet of vehicles, this can translate to thousands of dollars in annual savings.

Example: A logistics company operating 50 trucks observed a 20% reduction in annual repair costs after switching to high-quality oils, with noticeable improvements in engine cleanliness and performance stability.

Longer Equipment Lifespan

High-quality lubricants protect internal components and slow wear, which extends the life of engines and machinery. This reduces capital expenses on replacements and avoids unexpected downtime that can disrupt operations.

Equipment Lifespan Comparison:

| Equipment Type | Standard Oil Lifespan | High-Quality Oil Lifespan |

|---|---|---|

| Fleet trucks | 6–8 years | 9–12 years |

| Construction machinery | 8–10 years | 12–15 years |

| Industrial generators | 10–12 years | 15–18 years |

| Agricultural tractors | 7–9 years | 11–14 years |

Insight: By extending equipment life, businesses can allocate savings from reduced replacements into other areas, such as operational upgrades, employee training, or technology investments.

Real-World Scenario: A construction firm using high-quality oils in heavy machinery reported machinery remaining fully operational 3–5 years longer than expected, significantly reducing capital replacement costs over time.

Improved Fuel Efficiency

High quality motor Oils and Lubricants reduce internal engine friction, enabling smoother power delivery and better energy conversion. This improves fuel efficiency, which is especially critical for businesses managing large fleets or fuel-intensive machinery.

Fuel Savings Comparison:

| Engine Type | Standard Oil Fuel Savings | High-Quality Oil Fuel Savings |

|---|---|---|

| Fleet vehicles | 0–2% | 2–6% |

| Industrial engines | 0–3% | 4–10% |

| Agricultural machinery | 0–2% | 3–7% |

Example Calculation:

A truck that consumes 30,000 liters of fuel per year would save 1,500 liters annually with a 5% efficiency improvement, translating into significant cost reduction over the vehicle’s lifetime.

Additional Benefit: Smoother engine operation also reduces strain on components, leading to longer service life and fewer breakdowns, creating a cycle of savings and efficiency.

Protection in Harsh Environments

Engines and machinery operating under extreme conditions, high temperatures, heavy loads, or dusty environments are at higher risk of damage. High-quality oils provide consistent protection and maintain their properties under these stresses.

Harsh Environment Performance:

| Condition | Standard Oil | High-Quality Oil |

|---|---|---|

| High temperature | Thins, loses protection | Maintains film and viscosity |

| Cold temperature | Thickens, slower flow | Stable, consistent lubrication |

| Dust exposure | Particles settle, wear rises | Traps contaminants for removal |

| Heavy load | Oil film weakens | Strong, pressure-resistant film |

Industry Insight: In sectors like construction, agriculture, and mining, premium oils can prevent costly engine failures, ensuring continuous operations even under extreme conditions.

Smoother Engine and Machinery Performance

Better lubrication results in quieter, more stable, and efficient engine operation. This enhances operator experience and reduces wear on connected systems such as transmissions and hydraulics.

| Feature | Standard Oil | High-Quality Oil |

|---|---|---|

| Noise levels | Moderate | Low |

| Temperature stability | Fluctuates | Stable |

| Power delivery | Uneven | Smooth |

| Engine cleanliness | Average | High |

| Component lifespan | Shorter | Longer |

Operational Benefit: A smoother-running engine requires less frequent adjustments and creates fewer disruptions in production workflows.

Long-Term Cost Comparison

When evaluating the total cost of ownership, premium oils often provide significant savings despite a slightly higher upfront purchase price. These savings come from reduced maintenance, fewer replacements, lower fuel consumption, and minimized downtime.

| Cost Factor | Standard Oil | High-Quality Oil |

|---|---|---|

| Purchase cost | Lower | Slightly higher |

| Maintenance | Higher | Lower |

| Part replacement | Frequent | Less frequent |

| Fuel consumption | Higher | Lower |

| Downtime | Higher | Lower |

| Total 5-year cost | High | Significantly lower |

Insight: Businesses that invest in high-quality oils typically see a measurable reduction in overall operating costs within the first few years, making the initial investment highly cost-effective.

Choosing the Right Oil

Selecting the correct oil for specific engines and machinery is crucial to maximizing performance and longevity. Key factors to consider include:

- Engine type and manufacturer specifications

- Operating temperature and climate conditions

- Workload, pressure, and duty cycles

- Fuel type (diesel, petrol, or alternative fuels)

- Age and service history of the equipment

- Recommended maintenance intervals

Matching oil properties to these factors ensures optimal protection, smoother performance, and tangible long-term cost benefits.

Industries Benefiting Most from High Quality Motor Oils and Lubricants

| Industry | Key Benefits |

|---|---|

| Transportation & Logistics | Reduced breakdowns, better fuel efficiency |

| Construction & Mining | Protection under heavy loads, extreme temps |

| Agriculture | Extended machinery life, smoother operation |

| Manufacturing | Reduced downtime, consistent output |

| Power Generation | Reliable operation over extended hours |

| Marine & Heavy Equipment | High-pressure protection, longer component life |

Operational Insight: Businesses in heavy-load or extreme-condition industries experience the highest immediate ROI from premium oils, often seeing extended service intervals and lower total operational costs.

FAQs

Can using premium lubricants extend the lifespan of machinery and engines?

Yes. Premium lubricants slow friction and wear, keeping engines and machinery operational for longer periods. For example, construction equipment using high-quality oil can operate 3–5 years longer than machines maintained with standard oil. Fleet vehicles experience fewer mechanical issues, reducing replacement costs and ensuring smoother operations. This translates to a lower total cost of ownership and more predictable budgeting for capital expenses.

Which types of engines or industries benefit most from high-quality oils?

Industries operating under heavy loads, extreme temperatures, or harsh environments benefit the most. This includes construction, mining, agriculture, transportation, power generation, and marine equipment. High-quality oils maintain viscosity and protective properties under stress, reduce wear, prevent overheating, and ensure continuous operation. Businesses in these sectors see the highest return on investment when switching to premium lubricants.

How do high-quality oils improve fuel efficiency?

Premium oils reduce internal engine friction, allowing engines to convert fuel more efficiently into power. Smoother operation leads to measurable fuel savings, typically 2–6% for fleet vehicles and 3–10% for industrial engines. Over time, this can save thousands of liters of fuel per year. Reduced friction also decreases component stress, indirectly extending engine life while lowering operational costs.

Are premium lubricants worth the higher upfront cost?

Absolutely. While premium oils may cost more initially, the long-term savings outweigh the upfront investment. High-quality oils reduce maintenance and repair costs, extend engine and machinery life, improve fuel efficiency, and minimize downtime. For businesses managing multiple vehicles or machines, these benefits result in substantial cost reduction, improved reliability, and predictable operational performance.

Final Thoughts

High Quality Motor Oils and Lubricants are one of the most effective investments for operational efficiency and cost savings. They:

- Reduce maintenance needs and repair costs

- Improve fuel efficiency, lowering operational expenses

- Extend equipment and engine lifespan

- Enable smoother operation in extreme or high-stress conditions

Using Nicopoil premium oils ensures predictable maintenance schedules, operational reliability, and measurable long-term savings. Businesses that adopt high-quality lubricants benefit not just from improved performance but from optimized cost management across the board.

By understanding and applying these principles, companies can maximize equipment value, maintain high operational uptime, and reduce the total cost of ownership in both the short and long term.